Disclaimer: The documents listed on this page are copyright-protected. By clicking on the [PDF] links below, you confirm that you or your institution have the right to access the corresponding pdf file.

Recent Papers

|

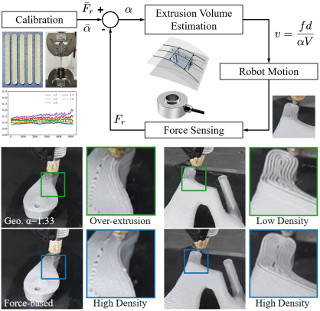

Yuming Huang, Renbo Su, Kun Qian, Tianyu Zhang, Yongxue Chen, Tao Liu, Guoxin Fang, Weiming Wang, and Charlie C.L. Wang, "Force-based adaptive deposition in multi-axis additive manufacturing: Low porosity for enhanced strength", Robotics and Computer-Integrated Manufacturing, vol.98, 103123 (13 pages), April 2026.

[Project]

[Video@YouTube]

Abstract Multi-axis additive manufacturing enhances mechanical strength by aligning printed layers with principal stress directions. However, this benefit introduces a key challenge: non-uniform layer thickness becomes inevitable due to surface curvature and deposition angle variations. Moreover, unpredictable errors in material deposition - such as inaccurate extrusion control, collapse of earlier deposited layers, or machine malfunctions - can accumulate throughout the build. These issues are difficult to model accurately in advance, making purely offline planning impractical for ensuring consistent print quality, especially in complex geometries. To address this issue, we propose a force-based adaptive deposition method that actively minimizes porosity during filament-based multi-axis AM. Our closed-loop control strategy dynamically adjusts the printhead feedrate based on real-time force feedback, while maintaining constant extrusion speed. Unlike geometry-driven offline planning approaches, our method compensates for thickness variation and process uncertainties, resulting in improved filament bonding. Experiments show up to a 72.1% increase in failure load compared to baseline methods, with similar or lower part weights. The approach also enhances robustness against extrusion irregularities, ensuring more consistent mechanical performance. |

|

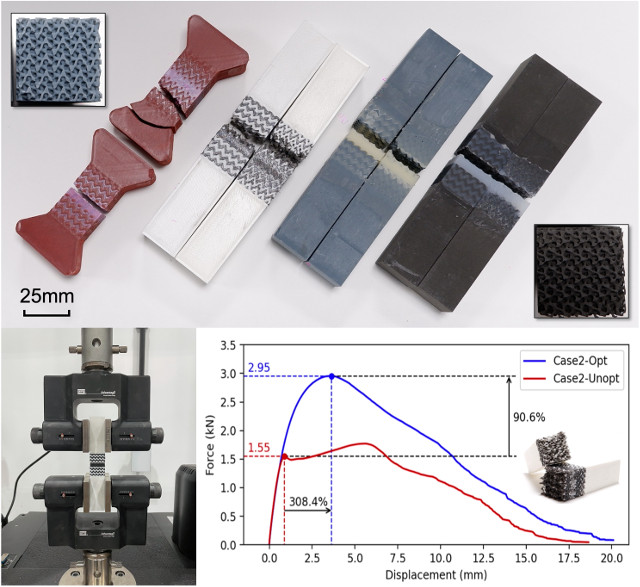

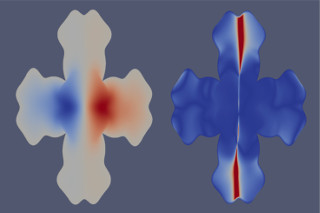

Renbo Su, Tao Liu, Tianyu Zhang, Yingjun Tian, Romain Hautier, Weiming Wang, and Charlie C.L. Wang, "TPMS-based mechanical bonding structures optimized by FEM with periodic boundary conditions", Materials & Design, vol.263, 115581 (17 pages), March 2026.

[Source Code]

Abstract Mechanical Bonding Structures (MBS) provide a reliable alternative to chemical bonding for joining dissimilar materials, enhancing mechanical performance and broadening design flexibility. This study introduces a novel approach to optimizing Triply Periodic Minimal Surfaces (TPMS)-based MBS using Finite Element Method (FEM) with Periodic Boundary Conditions (PBC). A hybrid TPMS-based representation is proposed, enabling topological and geometric variation to improve mechanical bonding performance. To address the challenges of non-periodic mesh and partial periodicity in FEA, a new PBC tool is developed, ensuring accurate numerical modeling of MBS. A data-driven optimization framework, incorporating Bayesian optimization, is applied to maximize the tensile strength of TPMS-based MBS. The proposed method is validated through mechanical tests on dual-material specimens fabricated via various manufacturing processes. Results demonstrate up to 109.5% improvement in tensile strength across different material combinations, confirming the effectiveness of the optimization strategy. This work provides a generalizable approach for designing high-performance MBS in multi-material manufacturing. |

|

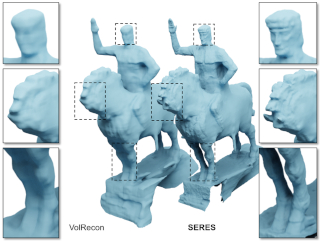

Bo Xu, Yuhu Guo, Yuchao Wang, Wenting Wang, Yeung Yam, Charlie C.L. Wang, and Xinyi Le, "SERES: Semantic-aware neural reconstruction from sparse views", IEEE Transactions on Visualization and Computer Graphics, vol.32, no.2, pp.2272-2283, February 2026.

[Project]

[arXiv]

Abstract We propose a semantic-aware neural reconstruction method to generate 3D high-fidelity models from sparse images. To tackle the challenge of severe radiance ambiguity caused by mismatched features in sparse input, we enrich neural implicit representations by adding patch-based semantic logits that are optimized together with the signed distance field and the radiance field. A novel regularization based on the geometric primitive masks is introduced to mitigate shape ambiguity. The performance of our approach has been verified in experimental evaluation. The average chamfer distances of our reconstruction on the DTU dataset can be reduced by 44% for SparseNeuS and 20% for VolRecon. When working as a plugin for those dense reconstruction baselines such as NeuS and Neuralangelo, the average error on the DTU dataset can be reduced by 69% and 68% respectively. |

|

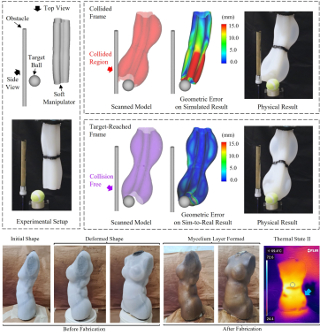

Yingjun Tian, Guoxin Fang, Renbo Su, Aoran Lyu, Neelotpal Dutta, Simeon Gill, Andrew Weightman, and Charlie C.L. Wang, "Correspondence-free, function-based sim-to-real learning for deformable surface control", IEEE Transactions on Robotics, vol.42, pp.653-672, December 2025.

[arXiv]

[Project]

[Video@YouTube]

Abstract This paper presents a correspondence-free, function-based sim-to-real learning method for controlling deformable freeform surfaces. Unlike traditional sim-to-real transfer methods that strongly rely on marker points with full correspondences, our approach simultaneously learns a deformation function space and a confidence map - both parameterized by a neural network - to map simulated shapes to their real-world counterparts. As a result, the sim-to-real learning can be conducted by input from either a 3D scanner as point clouds (without correspondences) or a motion capture system as marker points (tolerating missed markers). The resultant sim-to-real transfer can be seamlessly integrated into a neural network-based computational pipeline for inverse kinematics and shape control. We demonstrate the versatility and adaptability of our method on both vision devices and across four pneumatically actuated soft robots: a deformable membrane, a robotic mannequin, and two soft manipulators. |

|

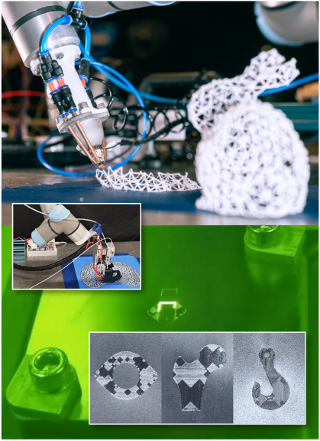

Yongxue Chen, Tao Liu, Yuming Huang, Weiming Wang, Tianyu Zhang, Kun Qian, Zikang Shi, and Charlie C.L. Wang, "Can any model be fabricated? Inverse operation based planning for hybrid additive-subtractive manufacturing", ACM Transactions on Graphics (SIGGRAPH Asia 2025), vol.44, no.6, article no.191 (14 pages), December 2025.

[Project]

[arXiv]

[Video@YouTube]

Abstract This paper presents a method for computing interleaved additive and subtractive manufacturing operations to fabricate models of arbitrary shapes. We solve the manufacturing planning problem by searching a sequence of inverse operations that progressively transform a target model into a null shape. Each inverse operation corresponds to either an additive or a subtractive step, ensuring both manufacturability and structural stability of intermediate shapes throughout the process. We theoretically prove that any model can be fabricated exactly using a sequence generated by our approach. To demonstrate the effectiveness of this method, we adopt a voxel-based implementation and develop a scalable algorithm that works on models represented by a large number of voxels. Our approach has been tested across a range of digital models and further validated through physical fabrication on a hybrid manufacturing system with automatic tool switching. |

|

Chengkai Dai, Tao Liu, Dezhao Guo, Binzhi Sun, Guoxin Fang, Yeung Yam, and Charlie C.L. Wang, "Curve-based slicer for multi-axis DLP 3D printing", ACM Transactions on Graphics (SIGGRAPH Asia 2025), vol.44, no.6, article no.194 (14 pages), December 2025. (Best Paper Award - Technical Papers)

[Project]

[arXiv]

[Video@YouTube]

Abstract This paper introduces a novel curve-based slicing method for generating planar layers with dynamically varying orientations in digital light processing (DLP) 3D printing. Our approach effectively addresses key challenges in DLP printing, such as regions with large overhangs and staircase artifacts, while preserving its intrinsic advantages of high resolution and fast printing speeds. We formulate the slicing problem as an optimization task, in which parametric curves are computed to define both the slicing layers and the model partitioning through their tangent planes. These curves inherently define motion trajectories for the build platform and can be optimized to meet critical manufacturing objectives, including collision-free motion and floating-free deposition. We validate our method through physical experiments on a robotic multi-axis DLP printing setup, demonstrating that the optimized curves can robustly guide smooth, high-quality fabrication of complex geometries. |

|

Tao Liu, Tianyu Zhang, Yongxue Chen, Weiming Wang, Yu Jiang, Yuming Huang, and Charlie C.L. Wang, "Neural co-optimization of structural topology, manufacturable layers, and path orientations for fiber-reinforced composites", ACM Transactions on Graphics (SIGGRAPH 2025), vol.44, no.4, article no.128 (17 pages), August 2025.

[Project]

[arXiv]

[Video@YouTube]

Abstract We propose a neural network-based computational framework for the simultaneous optimization of structural topology, curved layers, and path orientations to achieve strong anisotropic strength in fiber-reinforced thermoplastic composites while ensuring manufacturability. Our framework employs three implicit neural fields to represent geometric shape, layer sequence, and fiber orientation. This enables the direct formulation of both design and manufacturability objectives - such as anisotropic strength, structural volume, machine motion control, layer curvature, and layer thickness - into an integrated and differentiable optimization process. By incorporating these objectives as loss functions, the framework ensures that the resultant composites exhibit optimized mechanical strength while remaining its manufacturability for filament-based multi-axis 3D printing across diverse hardware platforms. Physical experiments demonstrate that the composites generated by our co-optimization method can achieve an improvement of up to 33.1% in failure loads compared to composites with sequentially optimized structures and manufacturing sequences. |

|

Li Yang, Weiming Wang, Ye Ji, Chun-Gang Zhu, and Charlie C.L. Wang, "Space-time isogeometric topology optimization with additive manufacturing constraints", Computer Methods in Applied Mechanics and Engineering, vol.441, 117976 (28 pages), June 2025.

Abstract This paper presents a novel space-time isogeometric topology optimization (ITO) framework for additive manufacturing, enabling concurrent optimization of structural shape and fabrication sequence with accurate geometric representation. The method integrates a density distribution function with a pseudo-time function to optimize build sequences for complex structures, with an objective function that minimizes compliance under external loads and accounts for self-weight effects during fabrication. Density values and virtual heat conduction coefficients are defined at B-spline control points to serve as design variables. A heat conduction-based formulation is employed to generate the pseudo-time function so that prevents the generation of isolated or floating material regions. A layer thickness constraint, defined by the pseudo-time gradient, further enhances manufacturability. The approach has been validated in 2D and 3D examples, demonstrating its effectiveness in managing objectives of entire structure's stiffness and self-weight of intermediate structures. |

|

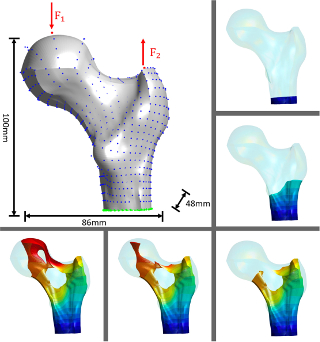

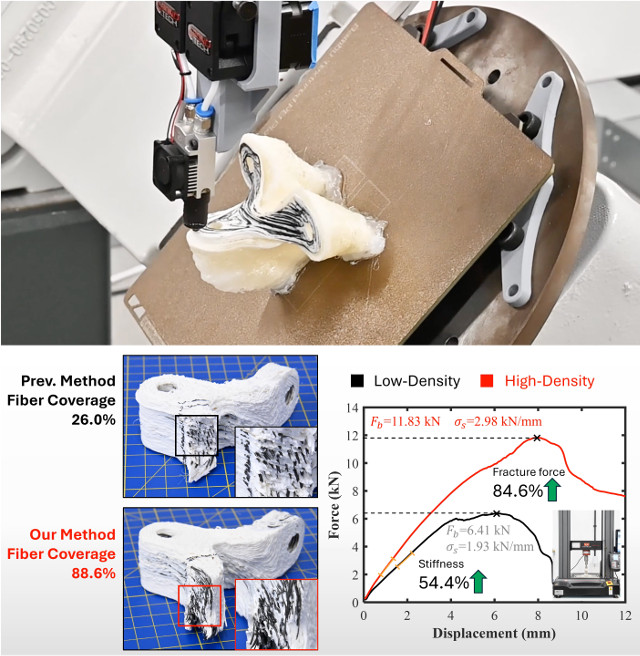

Tianyu Zhang, Tao Liu, Neelotpal Dutta, Yongxue Chen, Renbo Su, Zhizhou Zhang, Weiming Wang, and Charlie C.L. Wang, "Toolpath generation for high density spatial fiber printing guided by principal stresses", Composites Part B: Engineering, vol.295, 112154 (17 pages), April 2025.

[arXiv]

[Source Code]

[Video@YouTube]

Abstract While multi-axis 3D printing can align continuous fibers along principal stresses in continuous fiber-reinforced thermoplastic (CFRTP) composites to enhance mechanical strength, existing methods have difficulty generating toolpaths with high fiber coverage. This is mainly due to the orientation consistency constraints imposed by vector-field-based methods and the turbulent stress fields around stress concentration regions. This paper addresses these challenges by introducing a 2-RoSy representation for computing the direction field, which is then converted into a periodic scalar field to generate partial iso-curves for fiber toolpaths with nearly equal hatching distance. To improve fiber coverage in stress-concentrated regions, such as around holes, we extend the quaternion-based method for curved slicing by incorporating winding compatibility considerations. Our proposed method can achieve toolpaths coverage between 87.5% and 90.6% by continuous fibers with 1.1mm width. Models fabricated using our toolpaths show up to 84.6% improvement in failure load and 54.4% increase in stiffness when compared to the results obtained from multi-axis 3D printing with sparser fibers. |

|

Yongxue Chen, Tianyu Zhang, Yuming Huang, Tao Liu, and Charlie C.L. Wang,

"Co-optimization of tool orientations, kinematic redundancy, and waypoint timing for robot-assisted manufacturing",

IEEE Transactions on Automation Science and Engineering, vol.22, pp.12102-12117, April 2025.

[arXiv]

[Source Code]

[Video@YouTube]

Abstract In this paper, we present a concurrent and scalable trajectory optimization method to improve the quality of robot-assisted manufacturing. Our method simultaneously optimizes tool orientations, kinematic redundancy, and waypoint timing on input toolpaths with large numbers of waypoints to improve kinematic smoothness while incorporating manufacturing constraints. Differently, existing methods always determine them in a decoupled manner. To deal with the large number of waypoints on a toolpath, we propose a decomposition-based numerical scheme to optimize the trajectory in an out-of-core manner, which can also run in parallel to improve the efficiency. Simulations and physical experiments have been conducted to demonstrate the performance of our method in examples of robot-assisted additive manufacturing. |

|

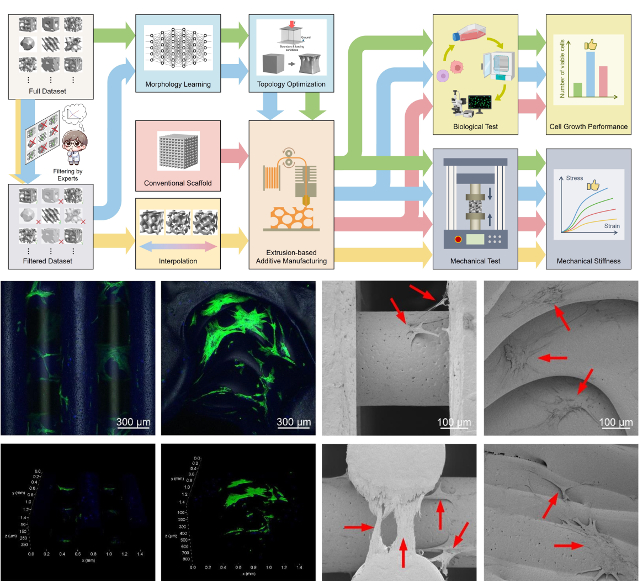

Weiming Wang, Yanhao Hou, Renbo Su, Weiguang Wang, and Charlie C.L. Wang, "Simultaneous topology optimization of differentiable and non-differentiable objectives via morphology learning: stiffness and cell growth on scaffold", Advanced Intelligent Discovery, March 2025.

[arXiv]

[Source Code]

[Dataset]

[Video@YouTube]

Abstract Topology optimization of microstructures plays a critical role in optimizing functional performance across diverse engineering applications. While metamaterials with enhanced mechanical properties - such as hyperelasticity, energy absorption, and thermal efficiency - are commonly designed using complex microstructural geometries and multi-physics simulations, achieving the simultaneous optimization of mechanical performance and non-differentiable objectives remains a significant challenge. In this work, we propose a novel framework for simultaneous topology optimization of differentiable and non-differentiable objectives via a data-driven morphology learning approach. The framework extracts shape patterns from a curated dataset of microstructures recognized for their superior performance in specific functional applications. To showcase the versatility of the approach, we apply it to the optimization of scaffolds for bone tissue engineering, with cell growth as a representative functional objective. |

|

Gang Xu, Xie Jin, Weizhen Zhong, Masahiro Toyoura, Ran Ling, Jinlan Xu, Renshu Gu, Charlie C.L. Wang, and Timon Rabczuk, "IGA-Graph-Net: Isogeometric analysis-reuse method based on graph neural networks for topology-consistent models", Journal of Computational Physics, vol.521, 113544 (18 pages), January 2025.

Abstract This paper introduces a novel isogeometric analysis-reuse framework called IGA-Graph-Net, which combines Graph Neural Networks with Isogeometric Analysis to overcome the limitations of Convolutional Neural Networks when dealing with B-spline data. Our network architecture incorporates ResNetV2 and PointTransformer for enhanced performance. We transformed the dataset creation process from using Convolutional Neural Networks to Graph Neural Networks. Additionally, we proposed a new loss function tailored for Dirichlet boundary conditions and enriched the input features. Several examples are presented to demonstrate the effectiveness of the proposed framework. In terms of accuracy when tested on the same set of partial differential equation data, our framework demonstrates significant improvements compared to the reuse method based on Convolutional Neural Networks for Isogeometric Analysis on topology-consistent geometries with complex boundaries. |

|

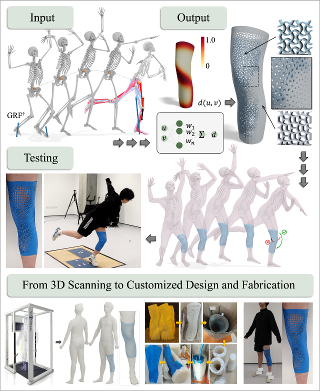

Xingjian Han, Yu Jiang, Weiming Wang, Guoxin Fang, Simeon Gill, Zhiqiang Zhang, Shengfa Wang, Jun Saito, Deepak Kumar, Zhongxuan Luo, Emily Whiting, and Charlie C.L. Wang,

"Motion-driven neural optimizer for prophylactic braces made by distributed microstructures", ACM SIGGRAPH Asia 2024, December 3-6, 2024, Tokyo, Japan.

[Project]

[arXiv]

[Video@YouTube]

Abstract Joint injuries, and their long-term consequences, present a substantial global health burden. Wearable prophylactic braces are an attractive potential solution to reduce the incidence of joint injuries by limiting joint movements that are related to injury risk. Given human motion and ground reaction forces, we present a computational framework that enables the design of personalized braces by optimizing the distribution of microstructures and elasticity. As varied brace designs yield different reaction forces that influence kinematics and kinetics analysis outcomes, the optimization process is formulated as a differentiable end-to-end pipeline in which the design domain of microstructure distribution is parameterized onto a neural network. The optimized distribution of microstructures is obtained via a self-learning process to determine the network coefficients according to a carefully designed set of losses and the integrated biomechanical and physical analyses. Since knees and ankles are the most commonly injured joints, we demonstrate the effectiveness of our pipeline by designing, fabricating, and testing prophylactic braces for the knee and ankle to prevent potentially harmful joint movements. |

|

Yuming Huang, Yuhu Guo, Renbo Su, Xingjian Han, Junhao Ding, Tianyu Zhang, Tao Liu, Weiming Wang, Guoxin Fang, Xu Song, Emily Whiting, and Charlie C.L. Wang,

"Learning based toolpath planner on diverse graphs for 3D printing", ACM Transactions on Graphics (SIGGRAPH Asia 2024), vol.43, no.6, article no.229 (16 pages), December 2024.

[Project]

[arXiv]

[Video@YouTube]

Abstract This paper presents a learning based planner for computing optimized 3D printing toolpaths on prescribed graphs, the challenges of which include the varying graph structures on different models and the large scale of nodes & edges on a graph. We adopt an on-the-fly strategy to tackle these challenges, formulating the planner as a Deep Q-Network (DQN) based optimizer to decide the next 'best' node to visit. We construct the state spaces by the Local Search Graph (LSG) centered at different nodes on a graph, which is encoded by a carefully designed algorithm so that LSGs in similar configurations can be identified to re-use the earlier learned DQN priors for accelerating the computation of toolpath planning. Our method can cover different 3D printing applications by defining their corresponding reward functions. Toolpath planning problems in wire-frame printing, continuous fiber printing, and metallic printing are selected to demonstrate its generality. The performance of our planner has been verified by testing the resultant toolpaths in physical experiments. By using our planner, wire-frame models with up to 4.2k struts can be successfully printed, up to 93.3% of sharp turns on continuous fiber toolpaths can be avoided, and the thermal distortion in metallic printing can be reduced by 24.9%. |

|

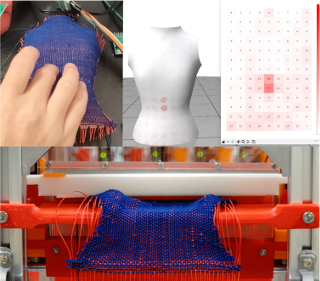

Xiangjia Chen, Lip M. Lai, Zishun Liu, Chengkai Dai, Isaac C.W. Leung, Charlie C.L. Wang, and Yeung Yam,

"Computer-controlled 3D surface weaving", Robotics and Computer-Integrated Manufacturing, vol.90, 102819 (12 pages), December 2024.

[arXiv]

[Video@YouTube]

Abstract In this paper, we present a new computer-controlled weaving technology that enables the fabrication of woven structures in the shape of given 3D surfaces by using threads in non-traditional materials with high bending-stiffness, allowing for multiple applications with the resultant woven fabrics. A new weaving machine and a new manufacturing process are developed to realize the function of 3D surface weaving by the principle of short-row shaping. A computational solution is investigated to convert input 3D freeform surfaces into the corresponding weaving operations (indicated as W-code) to guide the operation of this system. A variety of examples using cotton threads, conductive threads and optical fibres are fabricated by our prototype system to demonstrate its functionality. |

|

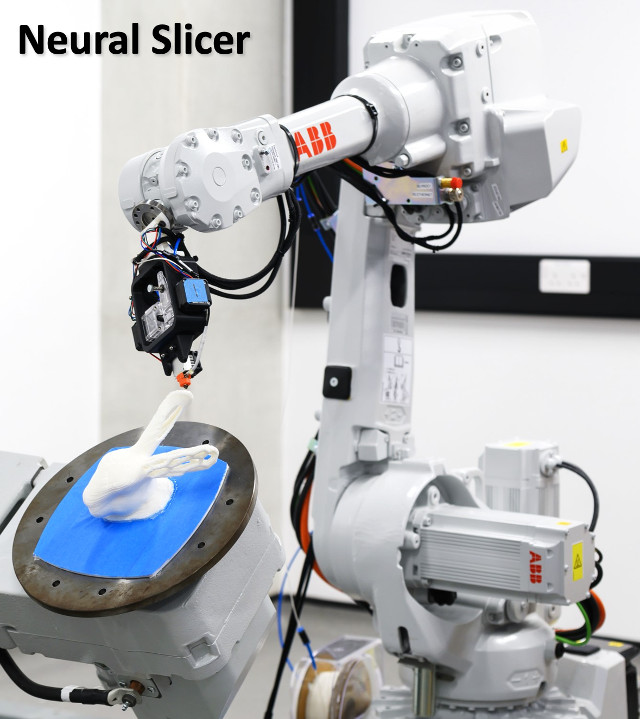

Tao Liu, Tianyu Zhang, Yongxue Chen, Yuming Huang, and Charlie C.L. Wang,

"Neural slicer for multi-axis 3D printing", ACM Transactions on Graphics (SIGGRAPH 2024), vol.43, no.4, article no.85 (15 pages), July 2024.

[Project]

[arXiv]

[Source Code]

[Video@YouTube]

Abstract We introduce a novel neural network-based computational pipeline as a representation-agnostic slicer for multi-axis 3D printing. This advanced slicer can work on models with diverse representations and intricate topology. The approach involves employing neural networks to establish a deformation mapping, defining a scalar field in the space surrounding an input model. Isosurfaces are subsequently extracted from this field to generate curved layers for 3D printing. Creating a differentiable pipeline enables us to optimize the mapping through loss functions directly defined on the field gradients as the local printing directions. New loss functions have been introduced to meet the manufacturing objectives of support-free and strength reinforcement. Our new computation pipeline relies less on the initial values of the field and can generate slicing results with significantly improved performance. |

|

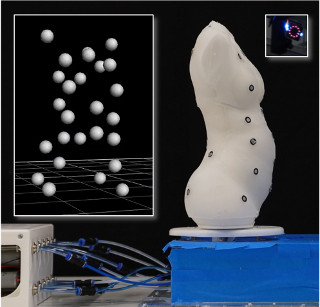

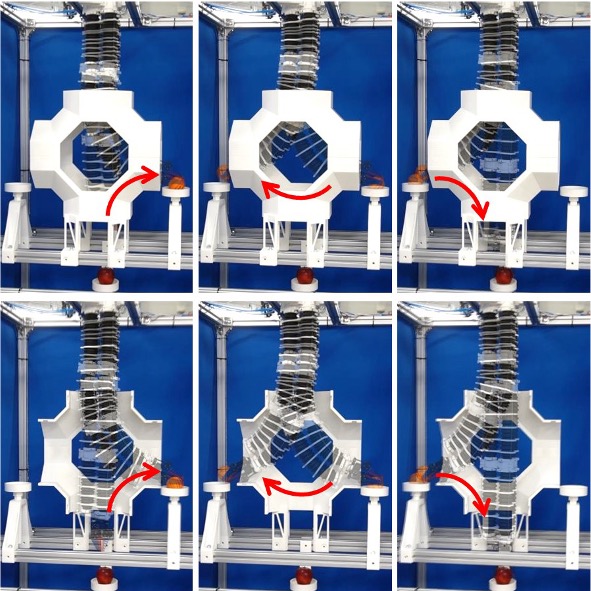

Yingjun Tian, Guoxin Fang, Renbo Su, Weiming Wang, Simeon Gill, Andrew Weightman, and Charlie C.L. Wang, "Function based sim-to-real learning for shape control of deformable free-form surfaces", Robotics: Science and Systems Conference, July 15-19, 2024, Delft, Netherlands.

[arXiv]

[Video@YouTube]

Abstract For the shape control of deformable free-form surfaces, simulation plays a crucial role in establishing the mapping between the actuation parameters and the deformed shapes. The differentiation of this forward kinematic mapping is usually employed to solve the inverse kinematic problem for determining the actuation parameters that can realize a target shape. However, the free-form surfaces obtained from simulators are always different from the physically deformed shapes due to the errors introduced by hardware and the simplification adopted in physical simulation. To fill the gap, we propose a novel deformation function based sim-to-real learning method that can map the geometric shape of a simulated model into its corresponding shape of the physical model. Unlike the existing sim-to-real learning methods that rely on completely acquired dense markers, our method accommodates sparsely distributed markers and can resiliently use all captured frames - even for those in the presence of missing markers. To demonstrate its effectiveness, our sim-to-real method has been integrated into a neural network-based computational pipeline designed to tackle the inverse kinematic problem on a pneumatically actuated deformable mannequin. |

|

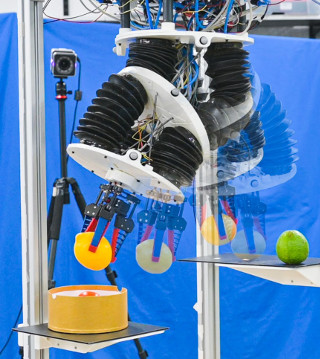

Yinan Meng, Guoxin Fang, Jiong Yang, Yuhu Guo, and Charlie C.L. Wang,

"Spring-IMU fusion based proprioception for feedback control of soft manipulators",

IEEE/ASME Transactions on Mechatronics, Focused Section on Compliant Mechanisms for Mechatronics, vol.29, no.2, pp.832-842, April 2024.

[arXiv]

[Video@YouTube]

Abstract This paper presents a novel framework to realize proprioception and closed-loop control for soft manipulators. Deformations with large elongation and large bending can be precisely predicted using geometry-based sensor signals obtained from the inductive springs and the inertial measurement units (IMUs) with the help of machine learning techniques. Multiple geometric signals are fused into robust pose estimations, and a data-efficient training process is achieved after applying the strategy of sim-to-real transfer. As a result, we can achieve proprioception that is robust to the variation of external loading and has an average error of 0.7% across the workspace on a pneumatic-driven soft manipulator. The realized proprioception on soft manipulator is then contributed to building a sensor-space based algorithm for closed-loop control. A gradient descent solver is developed to drive the end-effector to achieve the required poses by iteratively computing a sequence of reference sensor signals. A conventional controller is employed in the inner loop of our algorithm to update actuators (i.e., the pressures in chambers) for approaching a reference signal in the sensor-space. The systematic function of closed-loop control has been demonstrated in tasks like path following and pick-and-place under different external loads. |

|

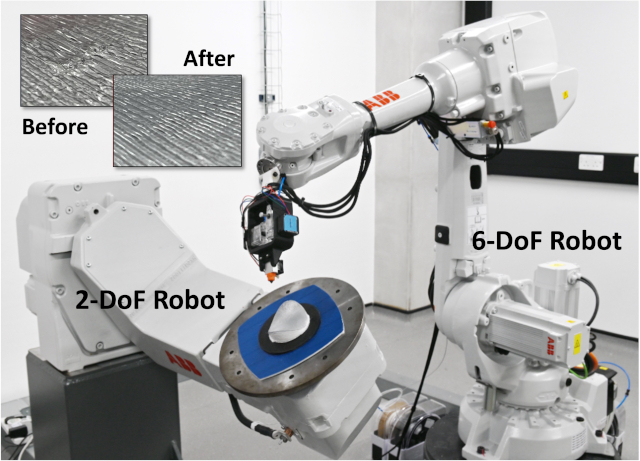

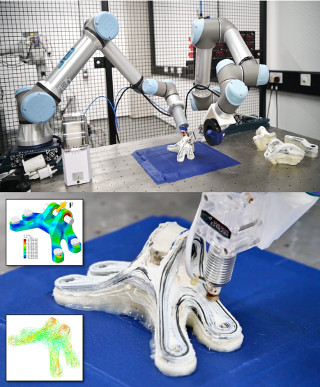

Guoxin Fang, Tianyu Zhang, Yuming Huang, Zhizhou Zhang, Kunal Masania, and Charlie C.L. Wang,

"Exceptional mechanical performance by spatial printing with continuous fiber: curved slicing, toolpath generation and physical verification", Additive Manufacturing, vol.82, 104048 (16 pages), February 2024. (Highly Cited Paper - Web of Science)

[arXiv]

[Video@YouTube]

[Project]

Abstract This work explores a spatial printing method to fabricate continuous fiber-reinforced thermoplastic composites (CFRTPCs), which can achieve exceptional mechanical performance. For models giving complex 3D stress distribution under loads, typical planar-layer based fiber placement usually fails to provide sufficient reinforcement due to their orientations being constrained to planes. The effectiveness of fiber reinforcement could be maximized by using multi-axis additive manufacturing (MAAM) to better control the orientation of continuous fibers in 3D-printed composites. Here, we propose a computational approach to generate 3D toolpaths that satisfy two major reinforcement objectives: 1) following the maximal stress directions in critical regions and 2) connecting multiple load-bearing regions by continuous fibers. Principal stress lines are first extracted in an input solid model to identify critical regions. Curved layers aligned with maximal stresses in these critical regions are generated by computing an optimized scalar field and extracting its iso-surfaces. Then, topological analysis and operations are applied to each curved layer to generate a computational domain that preserves fiber continuity between load-bearing regions. Lastly, continuous fiber toolpaths aligned with maximal stresses are generated on each surface layer by computing an optimized scalar field and extracting its iso-curves. A hardware system with dual robotic arms is employed to conduct the physical MAAM tasks depositing polymer or fiber reinforced polymer composite materials by applying a force normal to the extrusion plane to aid consolidation. When comparing to planar-layer based printing results in tension, up to 644% failure load and 240% stiffness are observed on shapes fabricated by our spatial printing method. |

|

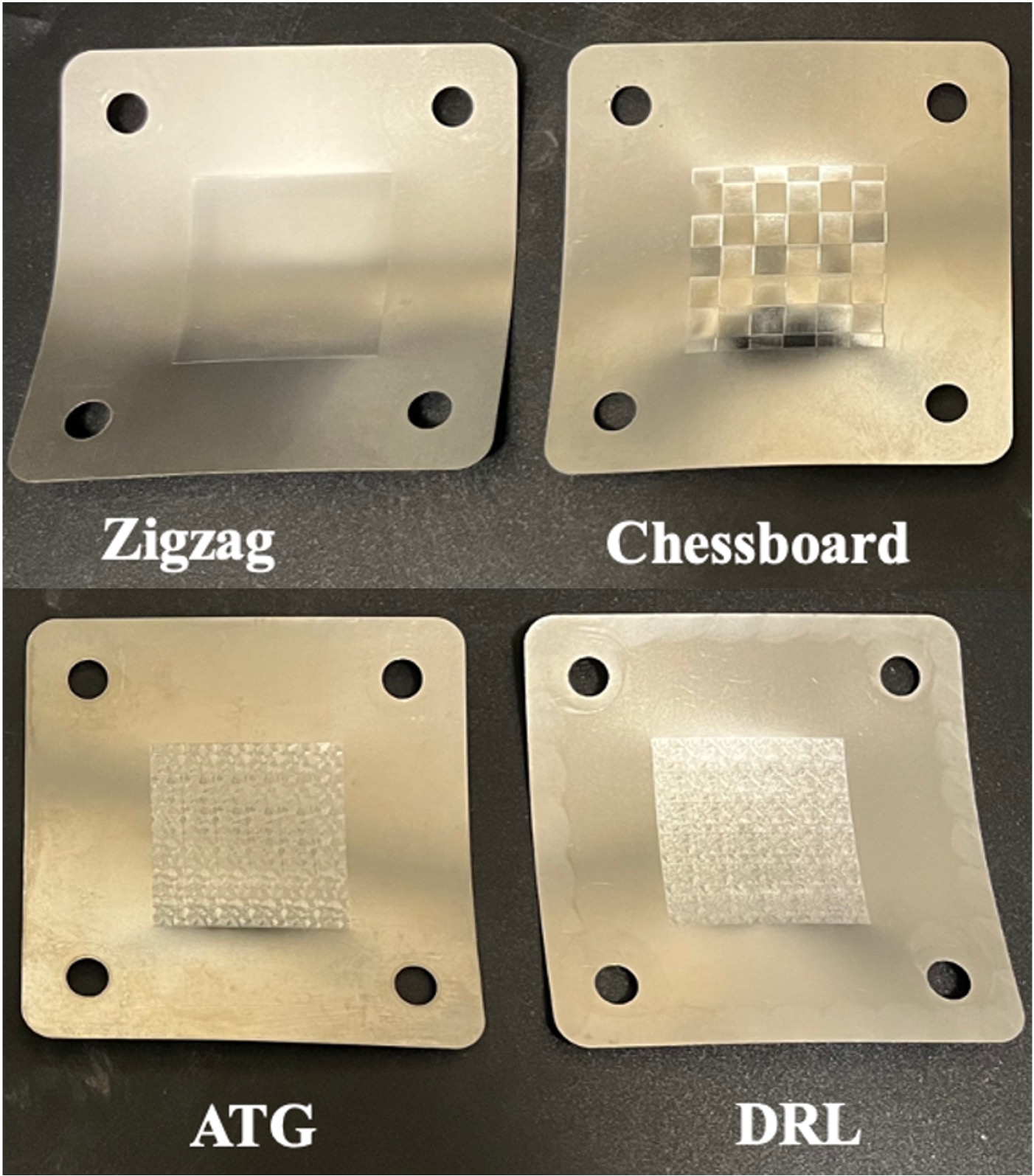

Mian Qin, Junhao Ding, Shuo Qu, Xu Song, Charlie C.L. Wang, and Wei-Hsin Liao, "Deep reinforcement learning based toolpath generation for thermal uniformity in laser powder bed fusion process", Additive Manufacturing, vol.79, 103937 (12 pages), January 2024. [arXiv]

Abstract Laser powder bed fusion (LPBF) is a widely used metal additive manufacturing technology. However, the accumulation of internal residual stress during printing can cause significant distortion and potential failure. Although various scan patterns have been studied to reduce possible accumulated stress, such as zigzag scanning vectors with changing directions or a chessboard-based scan pattern with divided small islands, most conventional scan patterns cannot significantly reduce residual stress. The proposed adaptive toolpath generation (ATG) algorithms, aiming to minimize the thermal gradients, may result in extremely accumulated temperature fields in some cases. To address these issues, we developed a deep reinforcement learning (DRL)-based toolpath generation framework, with the goal of achieving uniformly distributed heat and avoiding extremely thermal accumulation regions during the LPBF process. |

Under Review

|

Yinan Meng, Kun Qian, Jiong Yang, Renbo Su, Zhenhong Li, and Charlie C.L. Wang, "Sensor-space based robust kinematic control of redundant soft manipulator by learning", under review, July 2025.

[arXiv]

[Video@YouTube]

Abstract The intrinsic compliance and high Degree-of-Freedom (DOF) of redundant soft manipulators facilitate safe interaction and flexible task execution. However, effective kinematic control remains highly challenging, as it must handle deformations caused by unknown external loads and avoid actuator saturation due to improper null-space regulation - particularly in confined environments. In this paper, we propose a Sensor-Space Imitation Learning Kinematic Control (SS-ILKC) framework to enable robust kinematic control under actuator saturation and restrictive environmental constraints. We employ a dual-learning strategy: a multi-goal sensor-space control framework based on reinforcement learning principle is trained in simulation to develop robust control policies for open spaces, while a generative adversarial imitation learning approach enables effective policy learning from sparse expert demonstrations for confined spaces. To enable zero-shot real-world deployment, a pre-processed sim-to-real transfer mechanism is proposed to mitigate the simulation-to-reality gap and accurately characterize actuator saturation limits. Experimental results demonstrate that our method can effectively control a pneumatically actuated soft manipulator, achieving precise path-following and object manipulation in confined environments under unknown loading conditions. |